-High-performance TECNATOM SONIA UT electronics

-Phased Array and Multichannel inspection.

-Powerful TECNATOM software evaluation tools.

-Low Maintenance.

-Remote and local support.

-Integrated TECNATOM software suite for the complete inspection process.

-Seamless compatibility of all components.

-Connection to factory MES and databases.

-Wide variety of inspected components such as engine disks, turbine shafts, stiffeners, plates, billets, composites or bearings.

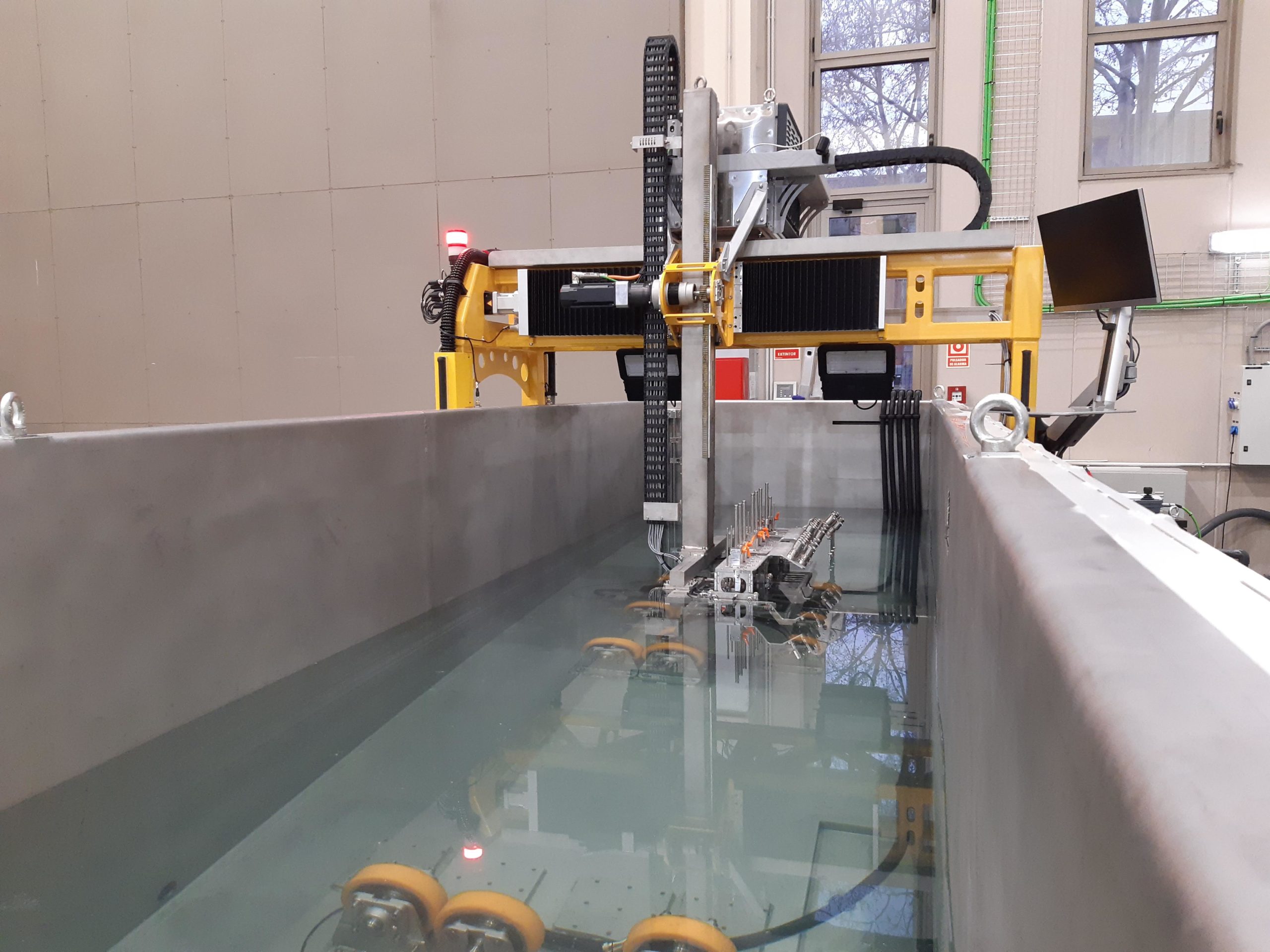

-Up to 8 automated axis: 3 linear, 3 for manipulator, and 2 for component rotation (turntable or rollers).

-2.5D & 3D inspection with CAD file import feature Ample range of frequencies including HF.

-Design customizable to customer specification.

-High quality industrial components of renowned suppliers.

-Heavy-duty proven system.

-TECNATOM proprietary technology.

-High mechanical repeatability.

-More than 20 references worldwide.

BACUS is an automated tank for the immersion inspection of a wide variety of aerospace and industrial components. It consists of a tank and gantry with a manipulator and optional component turntable or rotators (up to 8 automated axes configurable). Scan routines can range from simple 2D to 3D complex trajectories.

BACUS is suited for both through transmission and pulse-echo techniques with conventional or phased array electronics. Based on TECNATOM proprietary technology it enables a seamless and efficient inspection process. In short, BACUS means productive and reliable immersion inspections.